Products For Dyestuff

Dyes are compounds that can impart bright and durable colors to other substances in a molecular or dispersed state. In the printing and dyeing process, besides using raw dye powder, dye auxiliaries are also added to enhance dyeing efficiency and effectiveness. Among these auxiliaries, dye dispersants play a vital role. Dye dispersants are non-ionic surfactants that aid in achieving a leveling effect, maintaining dye dispersion, preventing aggregation and precipitation, and improving dye solubility. By incorporating dispersants and protective colloids, uniform dyeing is ensured, and stains are prevented.

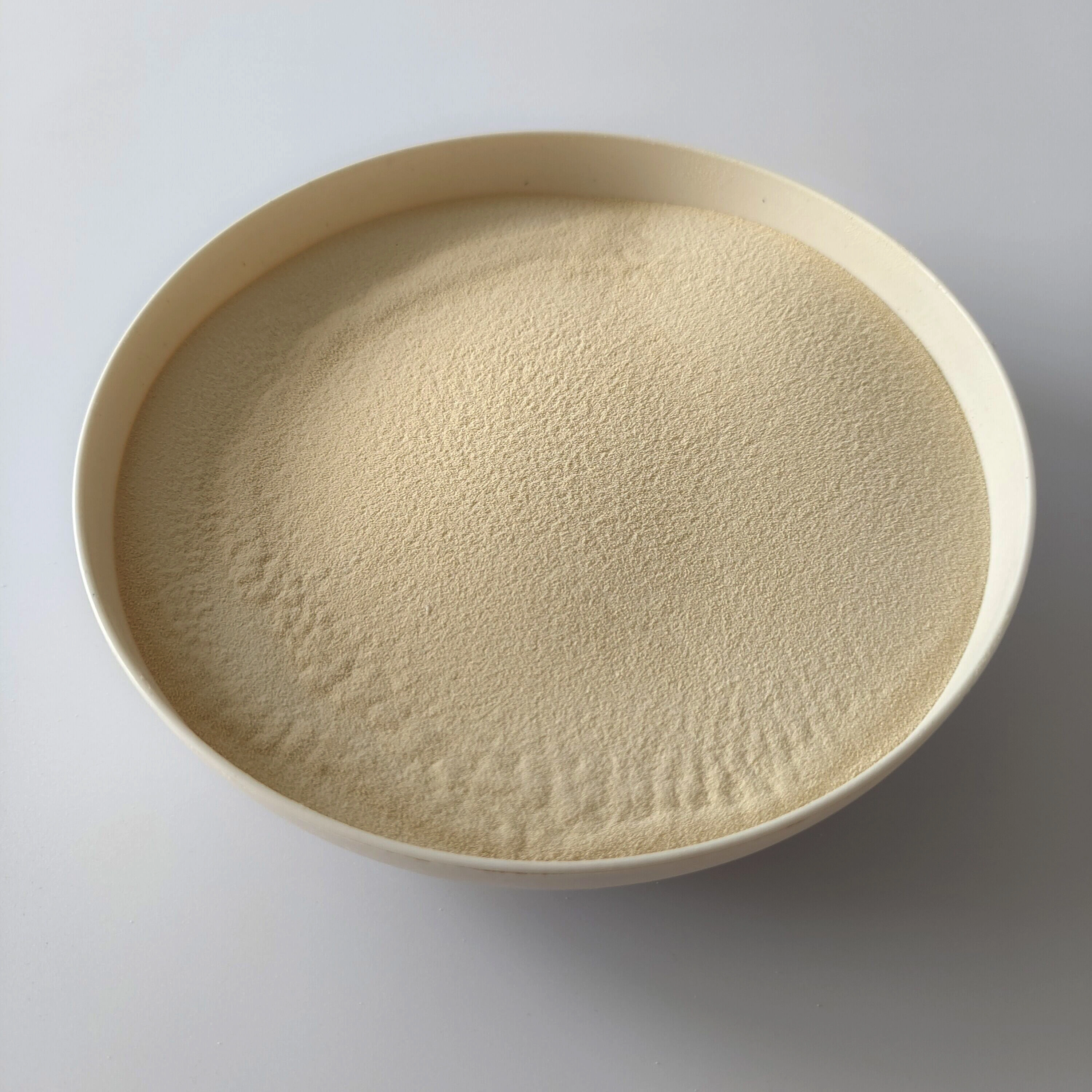

JUFU Chemical's Dyestuff Dispersant

Jufu offers three popular dispersant products, namely Dispersant NNO, Dispersant MF, and Dispersant SNF. These dispersants are primarily used as dispersants and fillers in disperse dyes, vat dyes, reactive dyes, acid dyes, and leather dyes. They exhibit excellent grinding effects, dispersibility, heat resistance, and dispersion stability at high temperatures. As a result, these products enhance the brightness, coloring power, and uniformity of dyes. Furthermore, our products can be combined with various dispersants to cater to the specific requirements of different disperse dyes and vat dyes.

Additionally, our lignosulfonate products are formaldehyde-free, non-toxic, and environmentally friendly. They contribute to achieving the desired thermal stability of dye particles and can be used to adjust color intensity. Many customers choose our lignosulfonate products to improve the sustainability of their products and processes.

What is the difference between emulsifier and dispersing agent in textile?

In textiles, an emulsifier and a dispersing agent serve different roles in processing, though they both aid in the distribution of substances. An emulsifier helps to blend two immiscible liquids, such as oil and water, creating a stable mixture (emulsion) by reducing surface tension. It's often used in textile processing to ensure uniform application of finishes or dyes when oil-based substances are involved. In contrast, a dispersing agent aids in evenly distributing solid particles within a liquid medium, preventing them from clumping together. In textile dyeing, dispersing agents keep dye particles evenly suspended in the bath, ensuring uniform color distribution across the fabric. While emulsifiers target liquid-liquid mixtures, dispersing agents focus on solid-liquid systems.

Recommended Products

More Uses

English

English