Choosing the Right Silicone Defoamer Powder: Factors to Consider

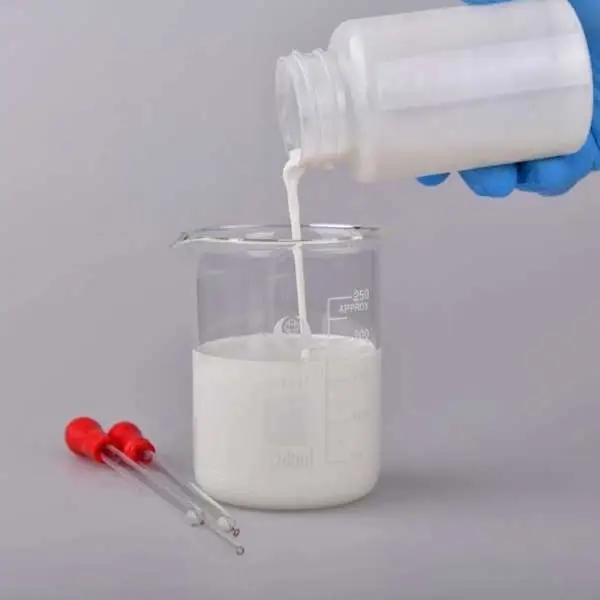

Introduction to Silicone Defoamer Powder

Silicone defoamer powder is a vital ingredient used in various industrial processes and manufacturing operations. It effectively eliminates foam and reduces the risk of machinery failures caused by foam accumulation. However, choosing the right silicone defoamer powder is crucial to ensure its compatibility with your specific applications. In this blog, we will discuss the key factors to consider when selecting the most suitable silicone defoamer powder for your needs.

Understanding Your Application Requirements

Before selecting a silicone defoamer powder, it is essential to have a comprehensive understanding of your application requirements. Consider the industry you operate in and the specific process in which the defoamer will be used. Different industries and applications may have varying foam-related challenges, such as excessive foam formation during coating, printing, or wastewater treatment. Assessing your needs will help you identify the defoamer powder formulation that meets your expectations.

Key Factors to Consider when Choosing Silicone Defoamer Powder

Application Compatibility

One of the primary factors to consider is the compatibility of the silicone defoamer powder with your existing process. Certain defoamers may have limitations based on temperature, pH, or chemical interactions. It is crucial to choose a powder that not only effectively defoams but also integrates smoothly into your current system, ensuring optimal performance.

Foam Control Efficiency

Different silicone defoamer powders exhibit varying levels of foam control efficiency. Assess the foam characteristics of your process and select a defoamer powder that demonstrates exceptional foam suppression capabilities. Look for products that provide long-lasting foam control, as this will enable uninterrupted operations with minimal interruptions.

Environmental Impact

Sustainability is an increasingly significant aspect of modern industries. Consider the environmental impact of the silicone defoamer powder you choose. Look for products that are formulated with biodegradable ingredients and have minimal impact on the surrounding ecosystem. Ensure that the manufacturer adheres to strict industry regulations and produces eco-friendly solutions.

Compatibility with Other Additives

In certain processes, other additives may be present alongside the silicone defoamer powder. It is crucial to ensure compatibility between the defoamer and any additional chemicals or substances used in your application. Some additives may interact adversely with the defoamer, affecting its efficacy or causing unwanted side effects. Verify compatibility beforehand to avoid potential issues.

Choosing the right silicone defoamer powder is crucial for efficient foam control in industrial processes. By understanding your application requirements, evaluating compatibility, foam control efficiency, environmental impact, and compatibility with other additives, you can make an informed decision. Investing in a reputable brand ensures that you are receiving a high-quality product that meets your specific needs. So, whether you are involved in coating, printing, wastewater treatment, or any other foam-related process, selecting the right silicone defoamer powder is essential for smooth operations and quality outcomes. Jufu Chemical provides high quality silicone defoamer powder at competitive price, feel free to contact us!

Recommended Products

Related News About Construction Chemicals

English

English