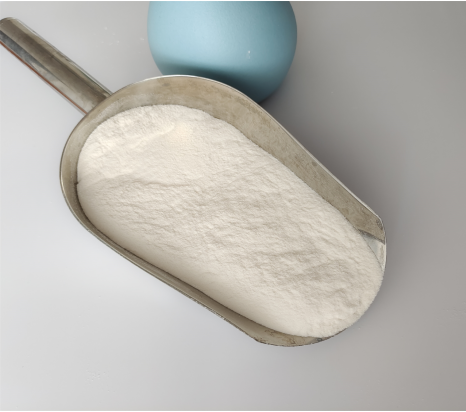

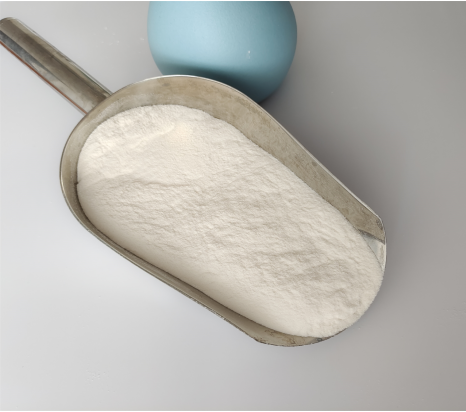

Main Uses And Dissolution Methods Of Hydroxypropyl Methyl Cellulose

Post Date:13,Jan,2025

Main uses of hydroxypropyl methyl cellulose (construction industry) :

1. Cement mortar: improve the dispersion of concrete sand, greatly improve the ductility and water solubility of cement mortar, prevent cracks, and improve the strength of cement

2. Tile cement: Improve the plastic deformation of the floor tile cement mortar, maintain water solubility, improve the compressive strength of the tile adhesive, and avoid delamination.

3. Suitable for asbestos and other refractory insulation materials: as a floating agent, improve fluidity, but also improve the hot joint compressive strength of the substrate.

4. Cooked stone concrete slurry: improve its water solubility and production and processing characteristics, improve the adhesion of the substrate.

5. Joint cement: Add gap concrete to the paper stone plate to improve mobility and water solubility.

6. Latex mud: Natural latex oil uses epoxy resin natural latex as raw material to improve fluidity and water solubility.

7. Gypsum: as a slurry in place of pure natural chemicals, it can improve water solubility and improve the relay race with base glue.

8. Paint: As a thickening agent for architectural latex paint, it can improve the actual operating characteristics and fluidity of architectural paint.

9. Spray painting: The concrete system or natural latex system and other fillers of water leakage prevention, improve fluidity and spray beam shape has a good practical effect.

10. Concrete and cooked stone have secondary products: as a hydraulic raw material of concrete-asbestos, press out molding adhesive, improve fluidity, uniform molding.

11. Fiber wall: Because of its antibacterial hydrolysis effect, it is very reasonable to use it as an adhesive for fluorocarbon coatings on external walls.

12. In addition: foaming curing agent (PC version), can be used to dilute balanced cement mortar and masonry operations.

Dissolution method of hydroxypropyl methyl cellulose:

1. All types and specifications of raw materials can be added by dry mixing;

2. When the solution needs to be added immediately at room temperature, choose the cold water dispersion type, which can be thickened within 10-90 minutes after adding;

3. General model, specification disperse with boiling water, stir in cold water and dissolve:

4. If caking and encapsulation occur during the dissolution process, it is due to the inadequate mixing of general models and specifications or the immediate addition of cold water. At this point, mix quickly.

5. If bubbles are produced during the dissolution process, they can be left to stand for 2-12 hours (the specific time is determined according to the concentration of the substance), or removed under pressure by vacuum packaging, or add appropriate amount of silicone defoamer.

Recommended Products

Related News About Construction Chemicals

English

English