Stable Growth Helps Boost Prosperity, The Industry Will Usher In Strong Reality

The commercialization and functional upgrading of concrete promote the growth of admixtures

Different from the relatively stable Demand curve of the cement industry, admixtures have certain growth potential, with the trend of increasing the total downstream demand and unit consumption. Admixtures are mainly used in ready-mixed concrete, and the increasing commercialization rate of concrete has led to a continuous increase in the total demand for admixtures. Since 2014, cement production has stabilized, but the production of commercial concrete has been increasing year by year, with an annualized growth rate of 12% in the past five years. Benefiting from policy promotion, more and more concrete demand scenarios are adopting commercial ready-mixed concrete. Centralized production of commercial concrete and transportation to the project site using mixer trucks are beneficial for achieving more accurate quality control, more scientific material proportioning, more convenient pouring construction, and effectively reducing environmental pollution caused by bulk cement in construction projects.

Product intergenerational upgrades provide tremendous growth potential for new product categories

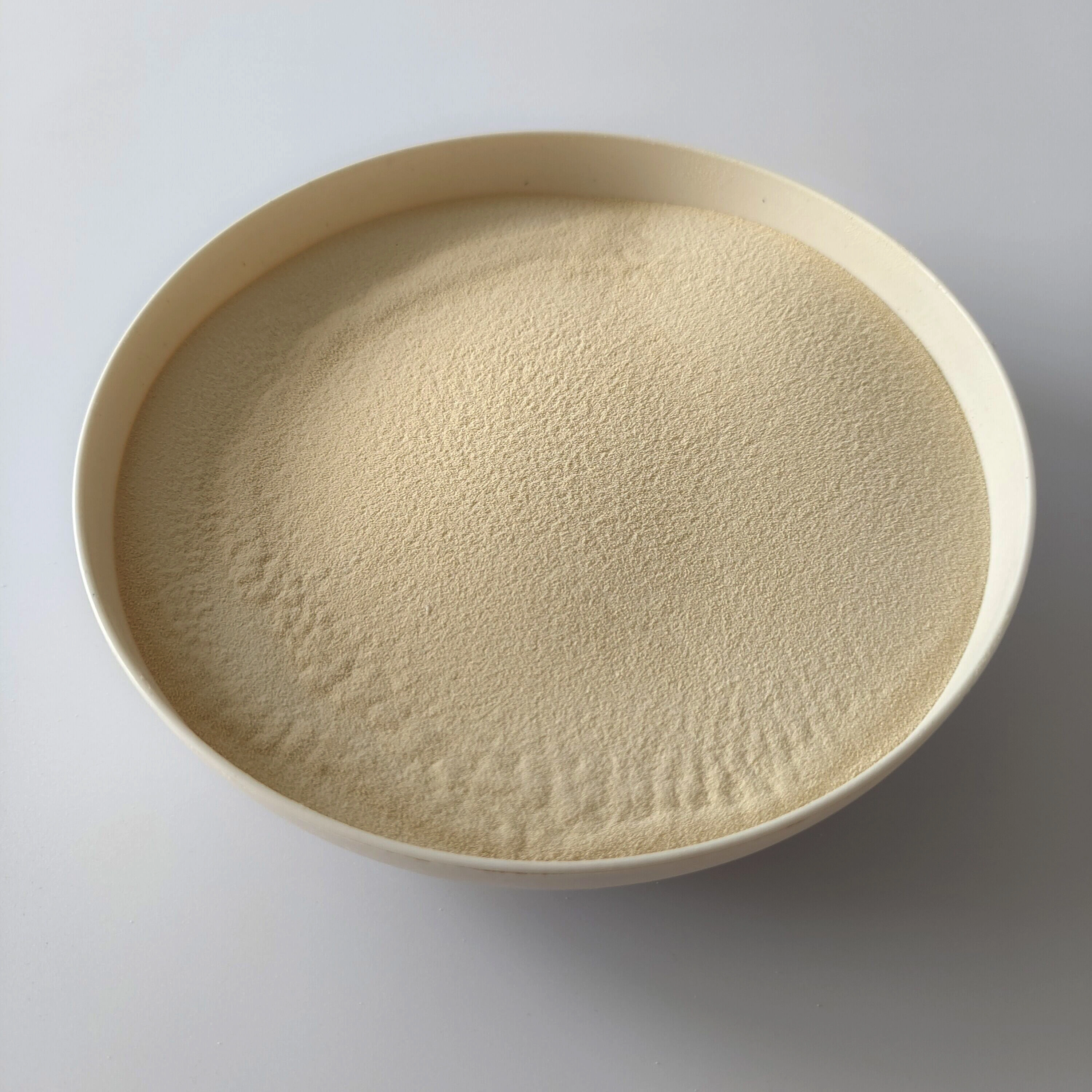

Water reducing agents themselves have strong growth potential, mainly due to the comprehensive replacement opportunities brought by the new generation upgrade. The third generation water reducing agent, also known as high-performance water reducing agent, with polycarboxylic acid as the main component, has gradually become the mainstream of the market. Its water reducing rate can reach over 25%, and its molecular freedom is large, with high customization degree and excellent flow promoting performance. This greatly improves the commercial feasibility of high-strength and ultra-high strength concrete, and therefore the proportion is increasing year by year.

The business model of the additive industry: customization and high viscosity

The target customers of water reducing agents are concrete manufacturers. There are mainly two types of groups, one is the commercial concrete manufacturer, whose business location is relatively fixed, mainly radiating the 50km area around the mixing station. This type of customer production facilities are usually located around the urban area, mainly serving real estate, urban public buildings, municipal engineering and other projects. The second is engineering clients, such as construction contractors for large-scale transportation infrastructure and water conservancy and hydropower projects. Due to the deviation of infrastructure projects from urban areas and scattered demand, construction companies usually build concrete mixing plants themselves instead of utilizing existing commercial concrete suppliers in the city.

Recommended Products

Related News About Construction Chemicals

English

English