What is the Difference Between PCE vs. Naphthalene-Based Plasticizer?

In the construction and concrete industries, the role of plasticizers cannot be overstated. These critical additives improve the workability, strength, and durability of concrete. Among the various types available, Polycarboxylate Ether (PCE) and Naphthalene-Based Plasticizers are two of the most prominent. Understanding their differences is essential for selecting the right plasticizer for specific applications. This article will delve into the contrasts between these two types of plasticizers, covering their chemical composition, performance characteristics, and suitability for various construction needs.

1. Chemical Composition: Polycarboxylate Ether (PCE) vs. Naphthalene-Based Plasticizer

Polycarboxylate Ether (PCE)

Polycarboxylate Ether (PCE) is a high-performance, water-reducing agent. PCE is composed of long-chain molecules with carboxyl groups that attach to the cement particles. These molecules provide superior dispersion characteristics, resulting in a higher degree of cement particle separation. The unique structure of PCE molecules allows for the creation of highly flowable concrete with a lower water-to-cement ratio. This feature is crucial in producing self-consolidating concrete (SCC) and high-performance concrete (HPC).

Naphthalene-Based Plasticizer

On the other hand, Naphthalene-Based Plasticizers are traditional water-reducing agents derived from sulfonated naphthalene formaldehyde condensates. The chemical structure of naphthalene-based plasticizers is relatively simpler compared to PCEs. These plasticizers work by surrounding cement particles with sulfonate groups, preventing them from clumping together. While effective in reducing water content and increasing workability, naphthalene-based plasticizers are less efficient than PCEs, particularly in high-performance applications.

2. Performance Characteristics: A Comparative Analysis

Water Reduction and Workability

When it comes to water reduction, PCE plasticizers outperform naphthalene-based plasticizers significantly. PCEs can achieve up to a 40% reduction in water content without compromising the workability of the concrete. This property is particularly advantageous in producing high-strength concrete with enhanced durability. Naphthalene-based plasticizers, while still effective, generally achieve a water reduction of around 20-25%. This makes them less suitable for applications requiring ultra-high strength and flowability.

Setting Time and Workability Retention

One of the key advantages of PCE plasticizers is their ability to maintain workability over a more extended period. This is especially important in large-scale construction projects where concrete must be transported over long distances or poured in complex structures. PCEs exhibit excellent slump retention, allowing for extended working times without the need for additional water. Conversely, naphthalene-based plasticizers tend to have a shorter slump retention time, often requiring retempering of the concrete mix, which can lead to a reduction in overall concrete quality.

Strength Development and Durability

Concrete treated with PCE plasticizers typically exhibits faster strength development and greater long-term durability. The superior dispersion of cement particles results in a denser microstructure, reducing porosity and increasing resistance to environmental factors such as freeze-thaw cycles, sulfate attack, and chloride penetration. Naphthalene superplasticizer, while still effective in improving concrete strength and durability, do not achieve the same level of performance as PCEs, particularly in demanding environments.

3. Suitability for Specific Applications

High-Performance Concrete (HPC) and Self-Consolidating Concrete (SCC)

For applications requiring High-Performance Concrete (HPC) or Self-Consolidating Concrete (SCC), PCE plasticizers are the preferred choice. Their ability to produce highly flowable, yet stable, concrete mixtures makes them ideal for these applications. The reduced water content and enhanced cement dispersion provided by PCEs contribute to the superior mechanical properties and durability required for HPC and SCC.

Mass Concrete and General Construction

In contrast, naphthalene-based plasticizers are more commonly used in mass concrete applications and general construction where the performance requirements are less stringent. These plasticizers offer a cost-effective solution for projects where moderate water reduction and workability improvement are sufficient. However, for projects requiring high strength and durability, naphthalene-based plasticizers may not meet the necessary performance standards.

Compatibility with Other Admixtures

Another important consideration is the compatibility of plasticizers with other admixtures used in concrete production. PCE plasticizers are known for their excellent compatibility with a wide range of admixtures, including air-entraining agents, retarders, and accelerators. This makes them versatile for use in various concrete formulations. Naphthalene-based plasticizers, however, may exhibit compatibility issues with certain admixtures, particularly when used in combination with high-performance concrete additives. This limitation can restrict their use in complex concrete formulations.

Choosing the Right Plasticizer for Your Project

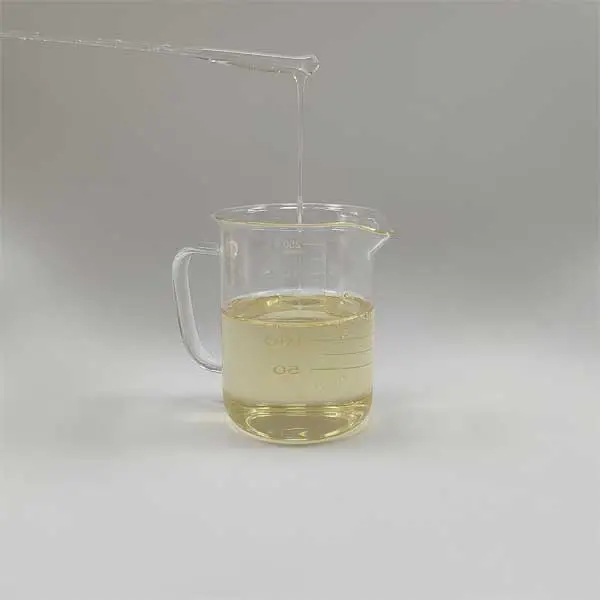

In summary, the choice between Polycarboxylate Ether (PCE) and Naphthalene-Based Plasticizers depends on the specific requirements of your construction project. PCE plasticizers are the superior choice for high-performance applications requiring maximum water reduction, extended workability, and enhanced durability. On the other hand, naphthalene-based plasticizers provide a more cost-effective solution for general construction needs where moderate performance improvements are sufficient. JUFU Chemical provides high-quality polycarboxylate superplasticizer liquid and naphthalene superplasticizer at competitive price, feel free to contact us!

Recommended Products

Related News About Construction Chemicals

English

English