What is the difference between hydroxyethyl cellulose and carboxymethylcellulose?

Navigating the world of cellulose derivatives can feel like deciphering a foreign language. Two common names you may have come across are hydroxyethyl cellulose (HEC) and carboxymethylcellulose (CMC). At first glance, they might seem similar, but understanding their differences can make all the difference when choosing the right additive for your project. Let’s break down these cellulose derivatives and see how they stack up against each other.

What are Cellulose Derivatives?

Cellulose derivatives are modifications of natural cellulose, a polysaccharide found in plant cell walls. While cellulose itself is a robust material, it has limited uses in its natural form because it's insoluble in water. By chemically modifying cellulose, we can create derivatives like HEC and CMC that possess unique properties such as increased solubility, viscosity, and binding capabilities. These characteristics make them valuable across various industries, including food, pharmaceuticals, and personal care.

What is Hydroxyethyl Cellulose (HEC)?

Hydroxyethyl cellulose is a non-ionic, water-soluble cellulose derivative. It is produced by reacting cellulose with ethylene oxide, which introduces hydroxyethyl groups onto the cellulose backbone. These groups increase the hydrophilicity of the polymer, allowing it to dissolve easily in water and form gels or thick solutions.

Properties and Characteristics

HEC is known for its excellent thickening, stabilizing, and film-forming properties. It is compatible with a wide range of surfactants, making it popular in personal care formulations like shampoos and lotions. The material is non-ionic, which means it won't react with other charged components in a solution, ensuring consistent performance across various applications.

hydroxyethyl cellulose powder

What is Carboxymethylcellulose (CMC)?

Carboxymethylcellulose is an anionic, water-soluble derivative of cellulose. It is synthesized by reacting cellulose with chloroacetic acid, which introduces carboxymethyl groups into the molecular structure. These groups confer a negative charge, giving CMC its unique properties, such as high water absorption and significant viscosity increase when dissolved.

Properties and Characteristics

CMC’s anionic nature means it can interact with other positively charged substances, making it suitable for a variety of uses, including food, pharmaceuticals, and detergents. It is widely used as a thickener, stabilizer, and binder, offering reliable performance even in challenging conditions.

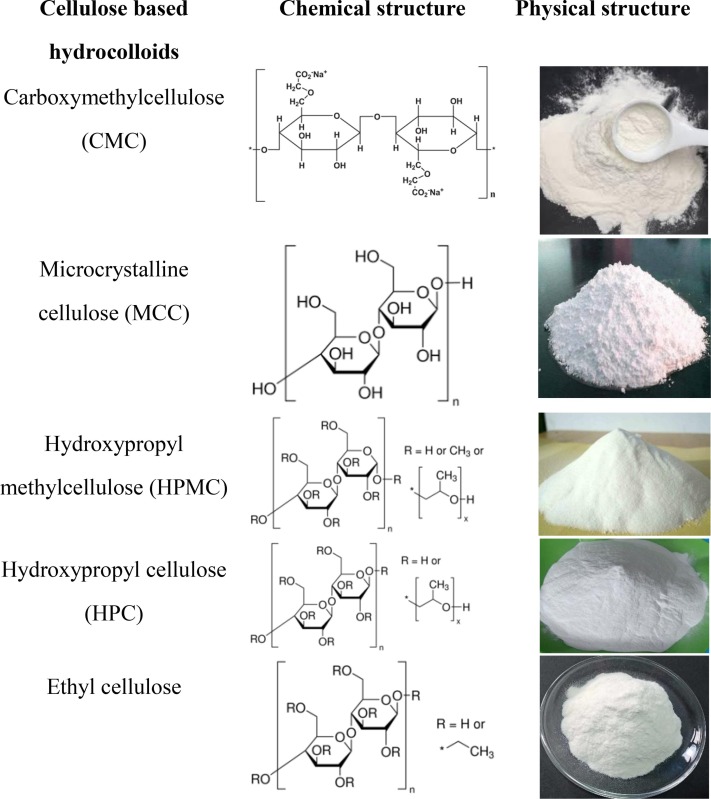

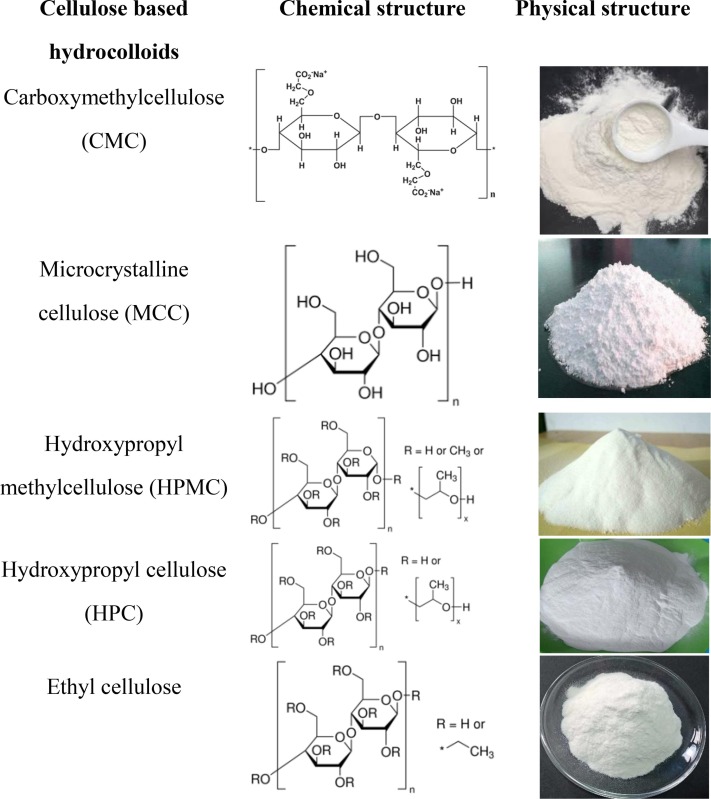

image from Science Direct

Chemical Structure Comparison

The key structural difference between HEC and CMC lies in their substituted groups:

HEC contains hydroxyethyl groups, making it non-ionic and more compatible with a broader range of ingredients.

CMC has carboxymethyl groups, which are anionic, allowing it to form electrostatic interactions with other compounds.

These structural differences impact their solubility, viscosity, and compatibility with other substances, influencing how they are used across industries.

Solubility and Viscosity Differences

While both HEC and CMC dissolve in water, they exhibit different behaviors:

HEC dissolves easily in both cold and warm water, forming a clear, non-gelling solution. Its viscosity is adjustable depending on the concentration, making it versatile for different formulations.

CMC dissolves readily in water, but the solution can form a gel-like consistency, depending on the molecular weight and degree of substitution. It offers a higher viscosity increase than HEC at the same concentration.

Rheological Properties

Rheology, or the study of flow behavior, is crucial when choosing between HEC and CMC:

HEC solutions are shear-thinning, meaning they become less viscous under shear stress (e.g., stirring). This property is beneficial in applications like paints, where easy spreading is desired.

CMC, on the other hand, can form more structured gels, providing a thicker consistency that is ideal for food products such as sauces and dairy alternatives.

Applications of Hydroxyethyl Cellulose

HEC is a versatile ingredient used in various industries:

Personal Care Products: HEC acts as a thickener and stabilizer in shampoos, conditioners, and lotions, improving the texture and feel.

Paints and Coatings: It helps control the viscosity and flow, ensuring even coverage and preventing drips.

Construction Materials: HEC is added to cement and plaster to improve workability and water retention.

Applications of Carboxymethylcellulose

CMC also has a wide range of uses, particularly in industries where thickening and stabilization are crucial:

Food Products: As a food-grade additive, CMC is used to thicken and stabilize products like ice cream, sauces, and baked goods.

Pharmaceuticals: It serves as a binder and disintegrant in tablets, enhancing the release of active ingredients.

Textiles: CMC is used in textile printing as a thickening agent for dyes and inks, ensuring precise patterns.

HEC vs. CMC in Personal Care Products

Both HEC and CMC can be found in personal care items, but their effects differ:

HEC provides a smooth, non-greasy texture in lotions and creams, making it ideal for products designed for sensitive skin.

CMC, with its gelling properties, is often used in toothpaste to give it a stable, uniform consistency.

HEC vs. CMC in Food Products

In the food industry, CMC tends to be the go-to choice due to its excellent stabilizing and thickening abilities. It helps prevent ice crystal formation in frozen foods, enhances the texture of baked goods, and improves the mouthfeel of beverages. HEC, while used less frequently in food, can still be found in certain applications where a non-ionic thickener is preferred.

Use in Pharmaceuticals

When it comes to pharmaceuticals, both HEC and CMC are valuable excipients:

HEC is often used in topical formulations like gels and creams due to its soothing properties.

CMC is a common ingredient in oral tablets and suspensions, helping to control the release of active ingredients.

Cost Comparison and Availability

In terms of cost, CMC is generally more affordable than HEC due to its widespread use and simpler production process. The price of HEC can be higher, especially for specialized grades used in pharmaceuticals or high-performance coatings.

How to Choose Between Hydroxyethyl Cellulose and Carboxymethylcellulose

Deciding between HEC and CMC depends on several factors:

Need for non-ionic vs. anionic properties: Choose HEC if a non-reactive thickener is needed; choose CMC if interactions with other charged ingredients are beneficial.

Desired viscosity: HEC is suitable for lower viscosity needs, while CMC provides a thicker consistency.

Cost constraints: CMC is often more budget-friendly.

Hydroxyethyl cellulose and carboxymethylcellulose are versatile cellulose derivatives with unique properties that make them suitable for different applications. While HEC offers non-ionic stability and compatibility across formulations, CMC provides robust thickening and gelling capabilities. Knowing the differences between these two can help you make an informed choice for your project.

Recommended Products

Related News About Construction Chemicals

English

English