Concrete is a critical material in modern construction, but it often needs a little help to reach its full potential. This is where additives like plasticizers and superplasticizers come into play. These powerful substances can drastically improve the performance of concrete, but they aren't the same thing. Knowing the difference can help you get the most out of your concrete, whether you're building a driveway or constructing a skyscraper.

Importance of Concrete Additives

Additives in concrete are like secret ingredients in a recipe—they might be a small part of the mix, but they have a huge impact on the final product. While plasticizers and superplasticizers both serve to enhance concrete's properties, they do so in different ways and to varying degrees.

Why Understanding the Difference Matters

Choosing the right additive can make all the difference in terms of cost, efficiency, and overall performance. Knowing when to use plasticizers versus superplasticizers can help avoid issues like cracking, low strength, or unnecessary expenses. It’s all about using the right tool for the job.

What is a Plasticizer?

Plasticizers are like the "stretching" agents of the concrete world, improving its flexibility and workability without changing too much about the rest of the mix.

Definition and Basic Functionality

A plasticizer, often referred to as a water reducer, is a chemical compound that reduces the amount of water needed to mix concrete while maintaining its workability. Think of it like adding a lubricant to a machine—it helps everything move more smoothly.

How Plasticizers Improve Concrete Workability

By lowering the water content without sacrificing fluidity, plasticizers enhance the ease of pouring and molding concrete. This means fewer air bubbles, better compaction, and a stronger final structure. They’re especially useful in projects where precision is key, such as detailed molds or small-scale applications.

Common Types of Plasticizers Used in Concrete

The most common plasticizers include lignosulfonates, which are derived from wood processing, and other natural-based compounds. These additives are ideal for everyday concrete applications where basic water reduction and slight improvements in strength are desired.

What is a Superplasticizer?

Superplasticizers take things to the next level, offering a dramatic improvement in concrete’s performance and capabilities.

Definition and Advanced Capabilities

Superplasticizers, also known as high-range water reducers, can reduce the water content in concrete by up to 30%, leading to significantly increased fluidity and slump. It’s like switching from a hand-mixer to a high-speed blender—the results are much smoother and more consistent.

How Superplasticizers Differ from Plasticizers

While both aim to reduce water content, superplasticizers are far more potent, making them ideal for high-performance concrete where strength and fluidity are paramount. Unlike plasticizers, they don’t just make the concrete workable; they make it flow like a liquid.

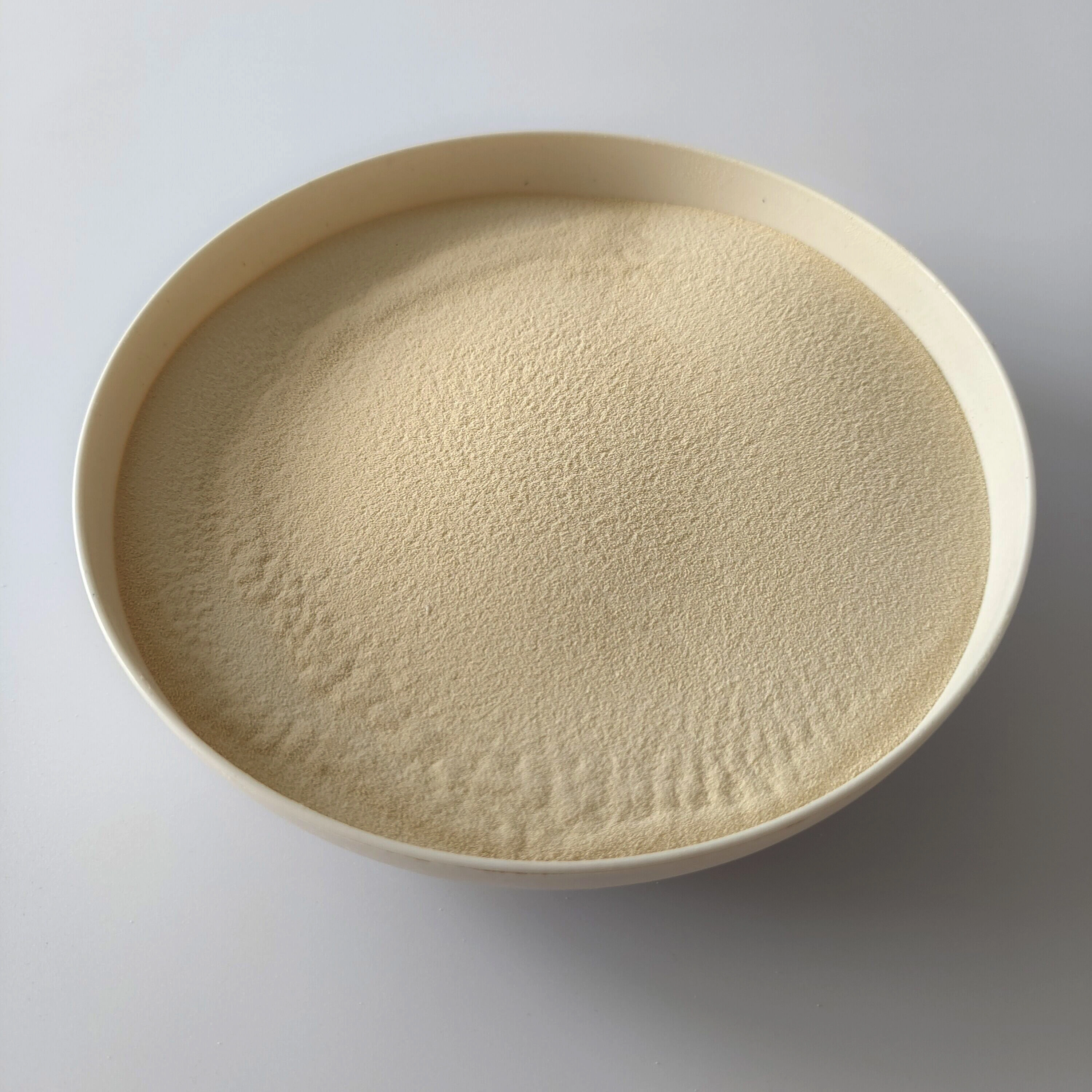

Common Types of Superplasticizers Used in Concrete

Some popular superplasticizers include polycarboxylate ethers (PCE powder), sulfonated melamine formaldehyde, and sulfonated naphthalene formaldehyde. These are often used in large-scale or high-stakes projects like bridges, high-rise buildings, and infrastructure projects requiring ultra-high strength.

Key Differences Between Plasticizers and Superplasticizers

Understanding the differences between these two types of additives can help you make more informed decisions in your construction projects.

Water Reduction Capabilities

Plasticizers typically reduce water content by 5-15%, while superplasticizers can achieve reductions of 20-30%. This significant difference impacts how fluid and workable the concrete becomes.

Impact on Concrete Strength and Durability

Superplasticizers allow for higher strength and denser concrete due to their ability to reduce water content more drastically. This is critical for projects where long-term durability and high load-bearing capacity are required.

Cost Implications and Efficiency

While superplasticizers are more effective, they are also more expensive than plasticizers. The choice depends on the project’s requirements—basic workability enhancements versus high-performance needs.

Applications of Plasticizers in Concrete

Plasticizers are great for standard concrete applications where some flexibility in workability is desired.

When to Use Plasticizers

They are commonly used in residential construction, sidewalks, patios, and other small-scale projects where enhancing the ease of mixing and pouring is beneficial.

Benefits of Plasticizers for Specific Projects

Plasticizers help reduce the risk of cracks and improve the surface finish. They also allow for more detailed molding in decorative concrete applications.

Applications of Superplasticizers in Concrete

Superplasticizers shine in projects where exceptional performance is a must.

When to Use Superplasticizers

They are essential for high-rise buildings, bridges, and other structures where concrete needs to flow easily into tight spaces without compromising on strength.

Advantages for High-Performance Concrete

Superplasticizers allow for the creation of self-compacting concrete (SCC), which can fill molds and forms without the need for vibration, making them ideal for complex or intricate shapes.

Choosing the Right Additive for Your Project

Picking between a plasticizer and a superplasticizer isn't just about budget—it’s about matching the right additive to the project’s specific requirements.

Factors to Consider When Selecting

Consider factors like the desired slump, strength, and setting time. If a higher slump and ultra-high strength are necessary, superplasticizers are the way to go.

Evaluating Project Requirements

Review the project’s size, complexity, and load-bearing needs. In large-scale projects, the extra cost of superplasticizers is often justified by the benefits they bring.

How Plasticizers and Superplasticizers Work Together

In some cases, using both can provide the best of both worlds.

Combining Both for Optimal Performance

By combining plasticizers with superplasticizers, you can achieve a balance of cost and performance. This method is often used in complex projects where different sections of concrete may have varying requirements.

Plasticizers and superplasticizers play crucial roles in modern construction, each offering unique benefits that cater to different project needs. While plasticizers are perfect for standard applications where a little extra flexibility is needed, superplasticizers provide high-performance solutions for large-scale, high-stakes projects. Understanding their differences ensures you can choose the right additive for your concrete mix, leading to better results and more efficient construction.

English

English